Production

Our production takes place in China. Four manufacturers contribute to making our products, as well as a printing house. In 2019, we moved our production from Vietnam to China because they can supply completely recycled fabrics and more sustainable options. Asia is the world leader in producing (recycled) synthetic fabrics and delivering high-quality manufacturing. Our ultimate goal is to produce locally. The realisation of local production relies on our search for new materials and the possibilities that come with it.

We appreciate the relationship with our Chinese partners and speak to our production manager daily. We have been learning a lot from them on a professional level and enjoy the teamwork. We visit our factories as often as possible for quality checks, to see the working conditions and to work together on improvements and sustainability. We went to China in 2019, and after a long COVID-related stop, we could finally visit again in 2023.

Zhejiang Province

Recycled fabrics

The production of our bags starts in the recycling factory, where raw materials are processed into yarns. We make recycled nylon (40D and 70D) and polyester (300D). Our recycled polyester thread is made from post-consumer waste, mainly plastic bottles and other plastic waste parts from clothing and bedding.

Our recycled nylon thread is made from pre-consumer waste. This waste comprises pieces from undyed and uncoated fabrics and thread remnants left after weaving nylon fabric.

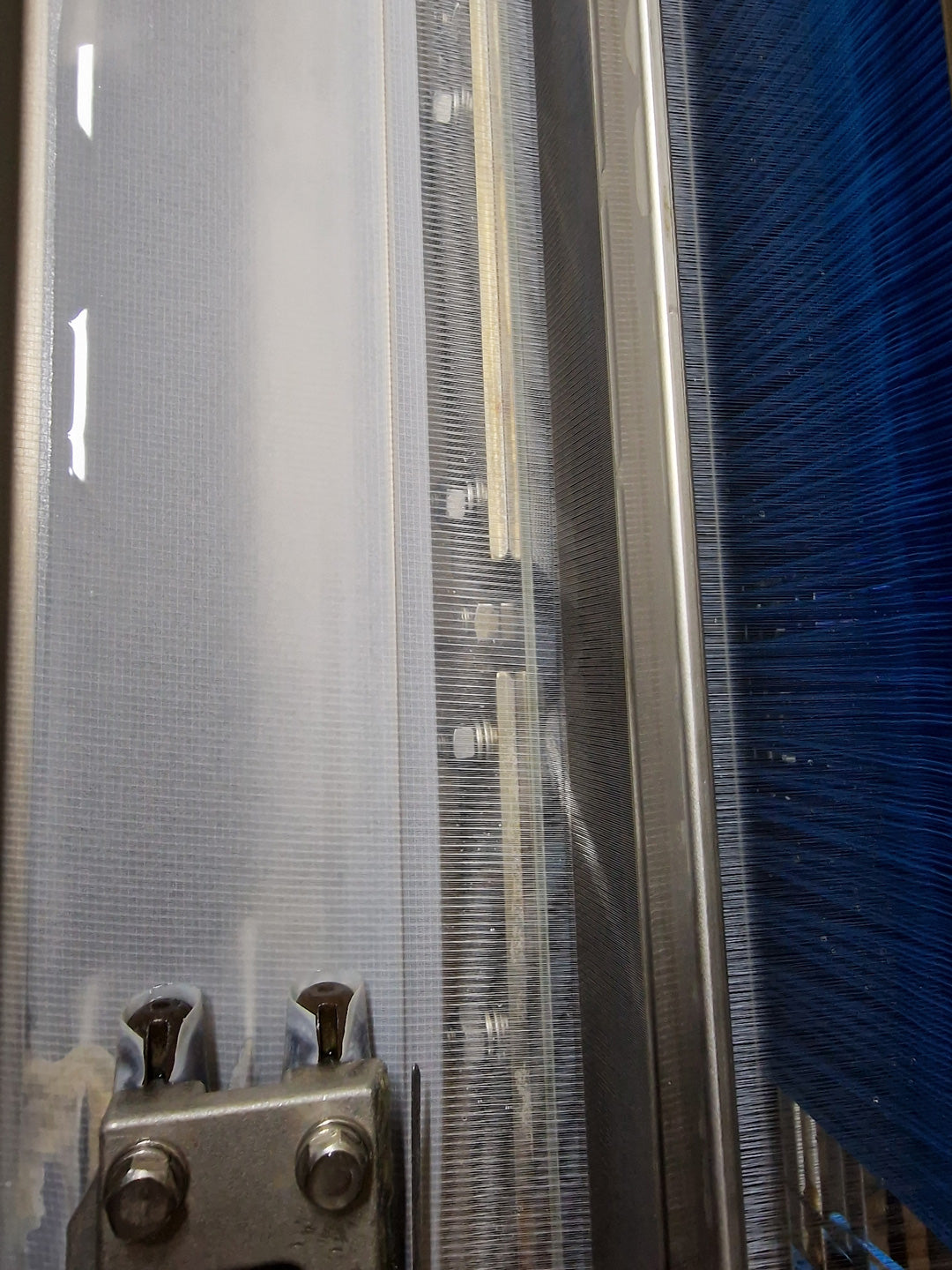

The threads are woven into our ripstop cloths in the greige-making part of the factory. Greige is the name for the grey/beige-ish colour of the undyed fabric. Ripstop means to 'stop' a 'rip'; ripstop fabrics are made with a reinforcing technique that makes them more resistant to tearing and ripping. During weaving, more robust (and often thicker) reinforcement yarns are interwoven regularly in a crosshatch pattern.

Our fabrics are certified with the Global Recycle Standard (GRS), an international standard that sets requirements for third-party certification of recycled input. The GRS is a complete product standard that dictates social and environmental best practices, chemical restrictions for fabrics, and more. Regarding the recycled content of garments, which is 100% in our bags, the GRS confirms a responsible use of resources and processes that have the least possible impact on human health and the planet.

Quanzhou, Fujian Province

Dyeing

From the greige factory, the fabric goes to the dye house, where Susan's selected colours come to life. Our dye house is Bluesign© certified. The Bluesign© system aims to find solutions for sustainable textile production by eliminating harmful substances at each step of the supply chain and approving chemicals, processes, materials, and products that are safe for the environment, the workers and customers. For example, all the water used in the process is thoroughly cleaned before it leaves the factory sewer.

Colour is essential to our brand; unfortunately, natural dyes give very limited colouring options, and using them would compromise our brand too much. We work with the next best option, which provides us with vibrant colours and is processed safely for humans and nature.

Suzhou, Jiangshu province

Coating

After the fabrics are coloured, they are sent to the coating house. The coating, applied to the inner side of the fabric, defines the hand feel of our material. It enhances the strength and durability of the fabric while providing water resistance or waterproofing.

Starting with the 2025 FLASH collection, we transitioned to a C0 fluorine-free (no fluorinated substances, including PFAS and others) PU coating on our 70D fabrics. The coating on 500D fabric is the same as on 300D fabric and is made from recycled TPE. The coating for 70D has been Bluesign-approved.

In previous collections that might still be in stock, our 70D and 40D coatings were a standard C6 PU coating.

We visit our factories as often as possible to maintain our relationship and quality standards and to work together on improvements and sustainability.

Danyang, Jiangsu Province

Sewing

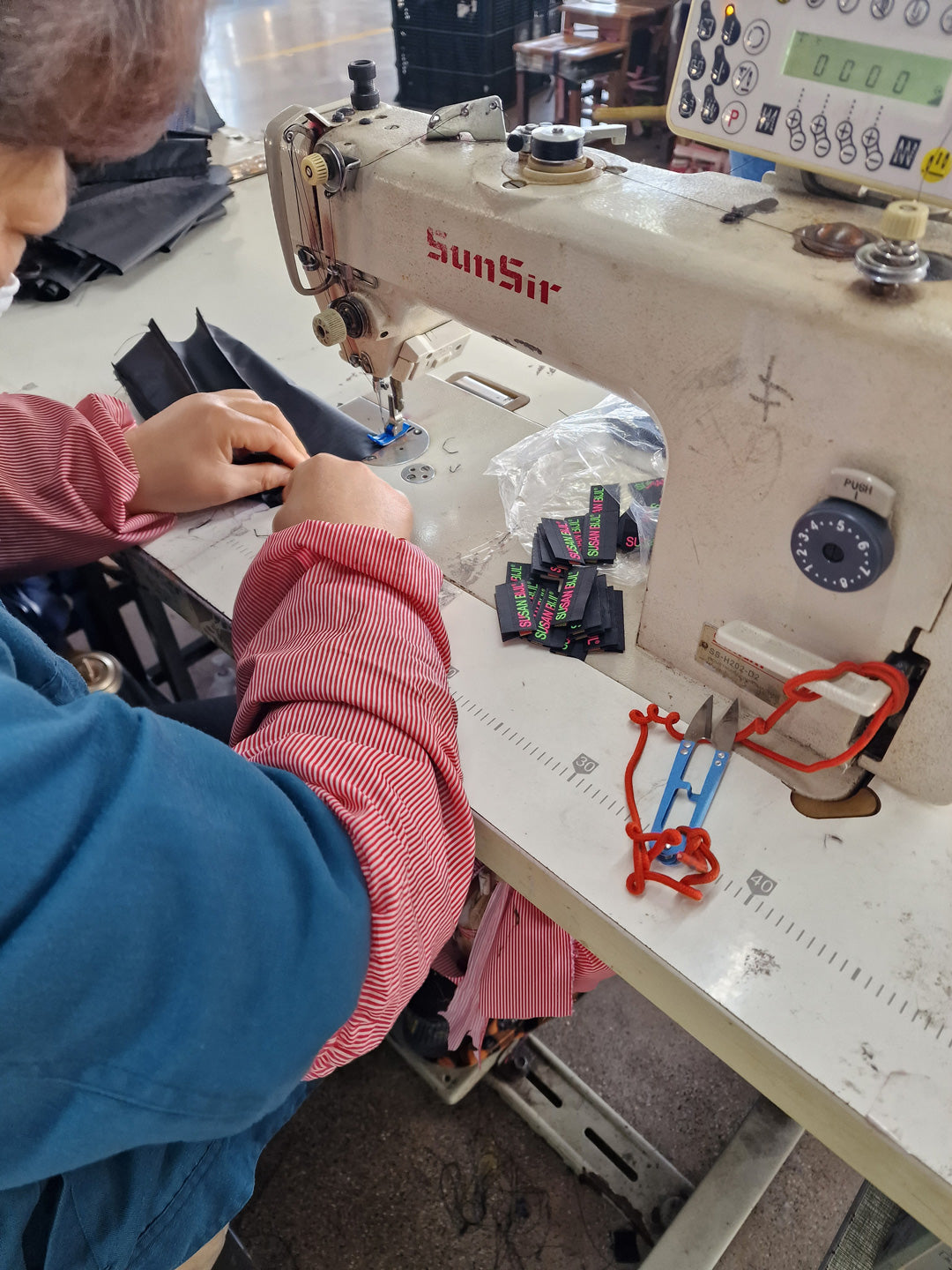

For the final stage, we arrive at the sewing factory, where the coloured and coated fabric is cut and sewed into bags. Our patterns are cut with moulds, making it possible to cut them very close together, resulting in very little fabric waste. Small parts like loops are made with the little leftovers they do have. Other elements like zippers and buttons are imported and chosen according to a recycled and high-quality standard.

We screen print our bags, if necessary, in the same area. We work with an environmentally friendly oil-based ink for our silkscreen prints. The ink base is polyvinyl alcohol (PVOH), a solvent-resistant polymer which is heavy metal-free and PVC free. We worked with an oil-based ink instead of a water-based ink because a water-based print would wear off nylon too quickly.

The construction of our bags is a significant part of manufacturing a durable bag. We design minimalistic yet complicated patterns so your bag will stay intact after a few years of usage. The people working in the sewing atelier are craftsmen who can deliver the quality we are looking for.

The sewing factory is BSCI (Business Social Compliance Initiative) certified for social compliance. The certificate is re-issued every year after the audit, including improvement points. BSCI aims to improve working conditions, such as the right to form a trade union, safe working conditions, and no forced or child labour.

Lastly, our paper packaging and hangtags are attached with a cotton string, and the collection is shipped to the Netherlands.

Questions

We update this page whenever we improve our production process. If you have any questions, please contact us at support@susanbijl.nl.